Introduction

Pharmaceutical equipment and drug simulation solutions can assist the pharmaceutical industry in pharmaceutical equipment development, new drug research and development, and achieving optimal benefits in manufacturing and quality control. We offer Ansys software for structural analysis, fluid analysis, product optimization, and more, applied to the following categories:

| Pharmaceutical Equipment Simulation |

1. Pharmaceutical Process Simulation: Pharmaceutical equipment simulation can be used to simulate the entire pharmaceutical process, including drug synthesis, powder mixing, granule preparation, tablet pressing, filling, sealing, and other processes. This helps optimize process parameters, improve product quality, and save costs.

2. Equipment Performance Assessment: Pharmaceutical equipment simulation can be used to assess the performance of different equipment, ensuring that they meet the required standards and predicting potential failures or improvement needs.

3. Equipment Cleaning and Disinfection Simulation: Equipment cleaning and disinfection are crucial in the pharmaceutical process. Simulation can help ensure that equipment meets standards and prevents cross-contamination.

| Drug Simulation Solutions |

1. Drug Molecular Simulation: These simulations can be used to predict the structure, interactions, and performance of drug molecules, accelerating the drug design and optimization process. Techniques like molecular dynamics simulation can model the motion and interactions between molecules.

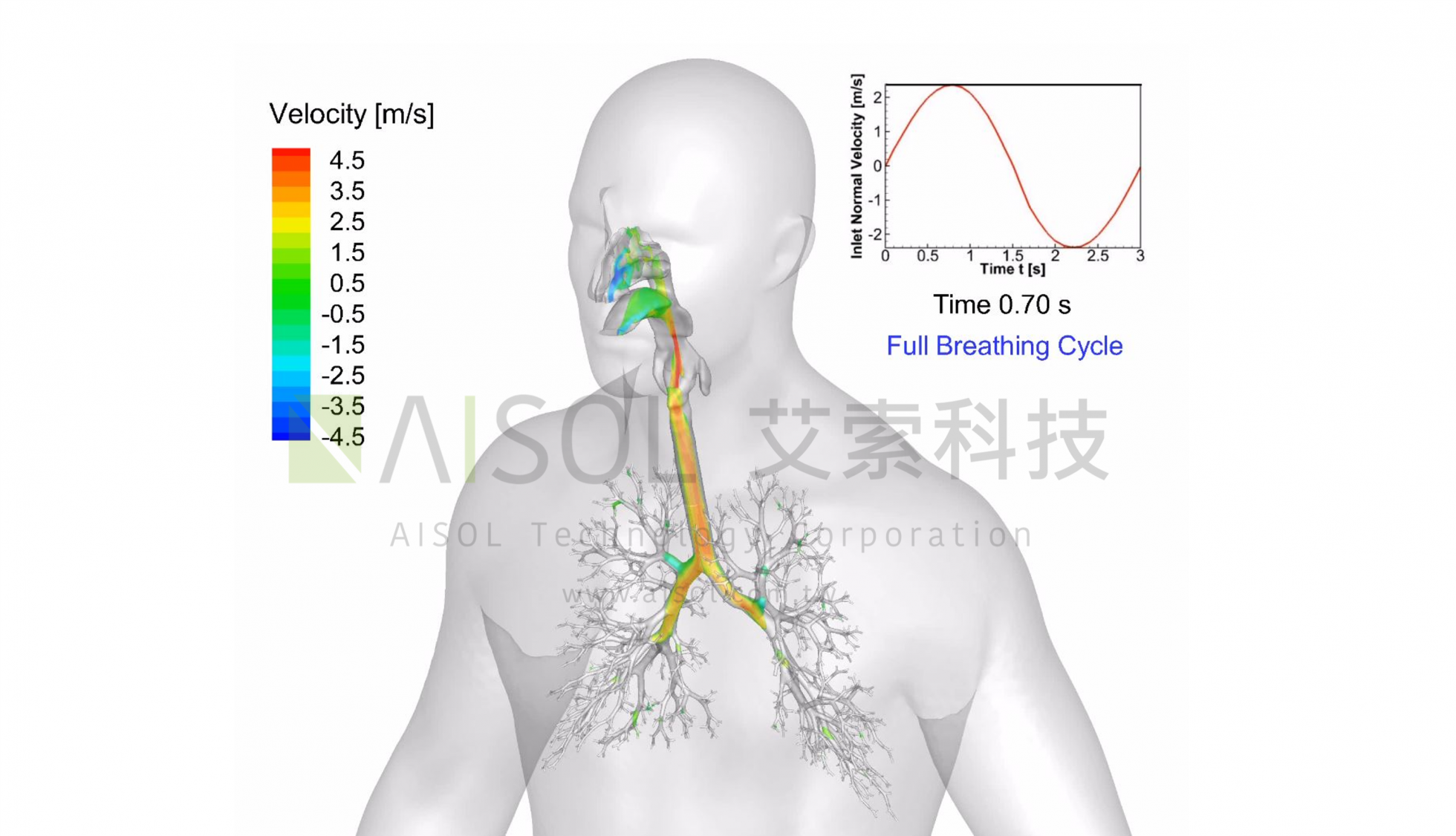

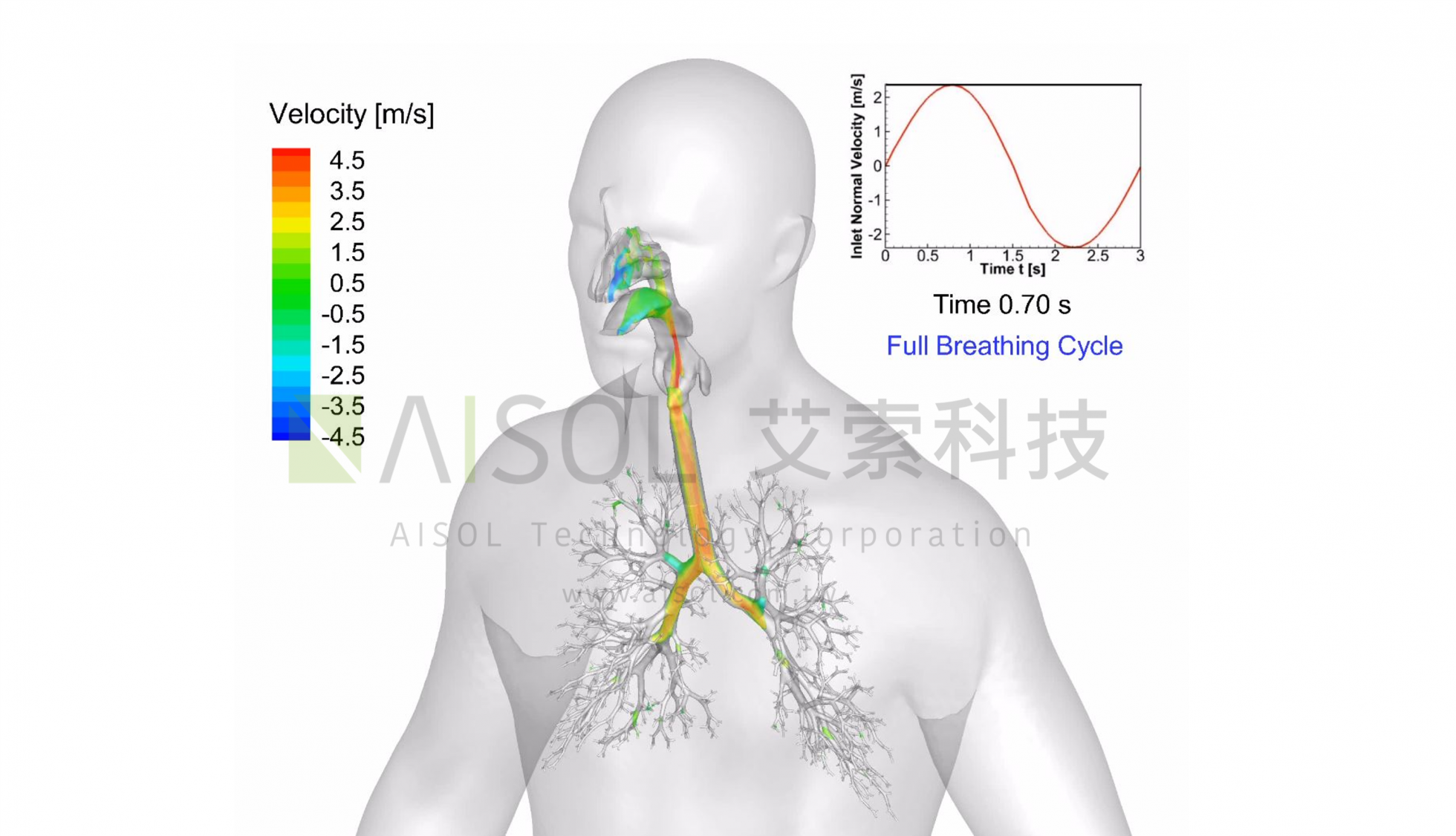

2. Drug Transport Simulation: Drug transport within the human body can be studied through simulation, including drug absorption, distribution, metabolism, and excretion (ADME). This helps understand the pharmacokinetics and toxicity of drugs.

3. Drug Release System Simulation: If drugs are used with specific release mechanisms (e.g., controlled or targeted release), simulation can assist in designing and optimizing these release systems to ensure drugs are released at the desired rate.

4. Drug Interactions and Side Effects Simulation: Simulation can be used to study interactions between different drugs and potential side effects they may have on the human body.

Features / strengths

1. Reducing Experimental Costs and Time: Simulation can reduce the need for laboratory testing, thus saving time and costs. This can accelerate the process of new drug development, allowing medicines to reach the market more quickly.

2. Optimizing Design and Processes: Pharmaceutical equipment simulation enables engineers to optimize the design of equipment and processes, enhancing performance, efficiency, and quality.

3. Ensuring Drug Efficacy: Simulation can be used to predict the performance, release characteristics, and behavior of drugs in the human body. This helps ensure that drugs achieve the desired effects.

4. Customized Medicine: Drug simulations can tailor treatment plans based on individual physiological characteristics and genotypes, enabling personalized medicine.

5. Enhancing Safety: Simulation can be employed to assess the safety of drugs and equipment, including potential toxicity and risks. This helps ensure the safe use of products.

6. Failure Analysis and Improvement: Equipment simulation can be used to analyze potential equipment failures, improving reliability and durability.

7. Reducing Animal Testing: Drug simulation can reduce the need for animal experiments, promoting ethical practices and reducing the use of animals.

8. Real-time Monitoring and Control: Simulation solutions can be used for real-time monitoring and control of pharmaceutical processes, ensuring stability and consistency in production.

9. Environmental Sustainability: Optimized pharmaceutical processes can reduce resource waste, minimize environmental impact, and achieve more sustainable production.

Specification in detail