Introduction

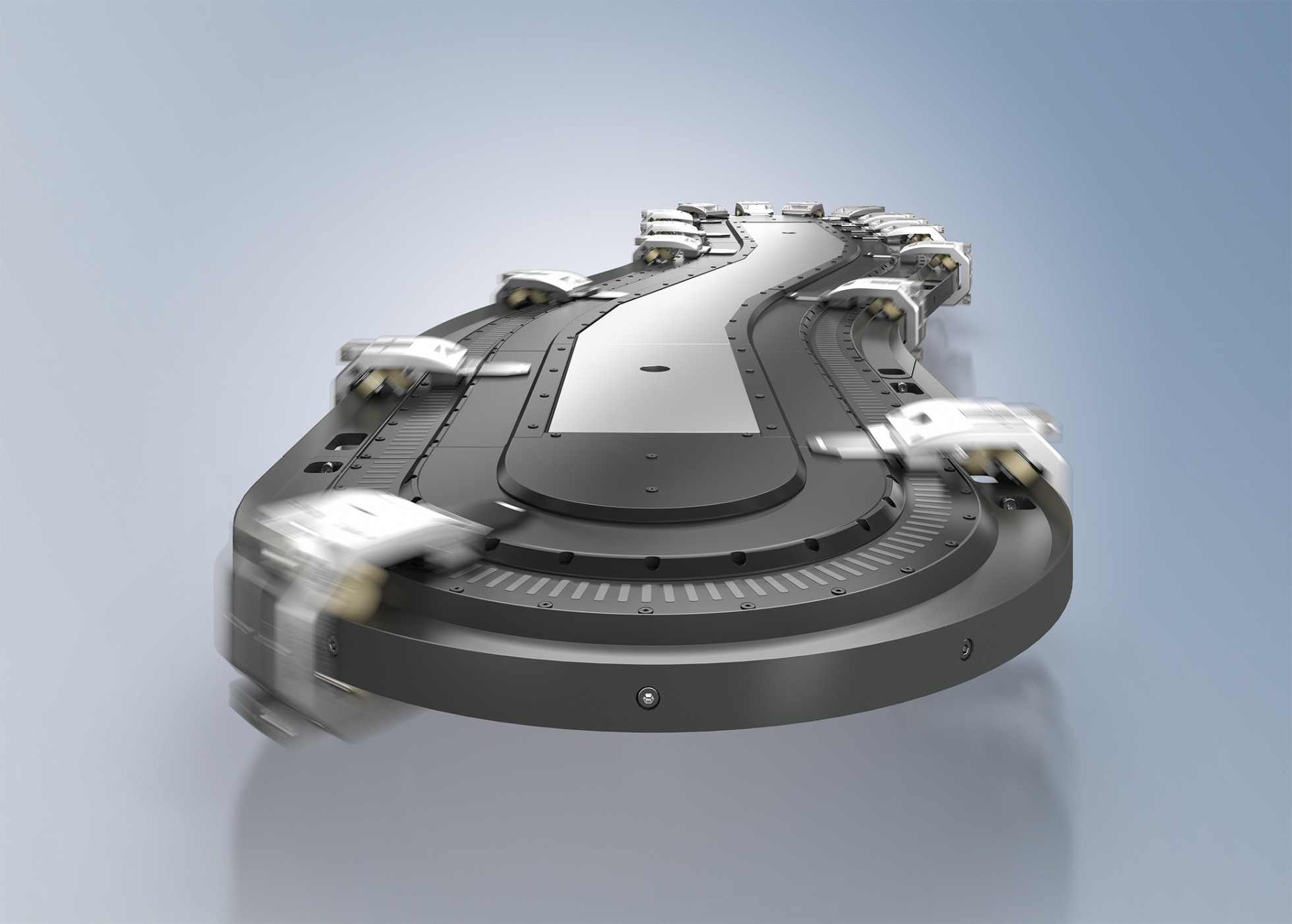

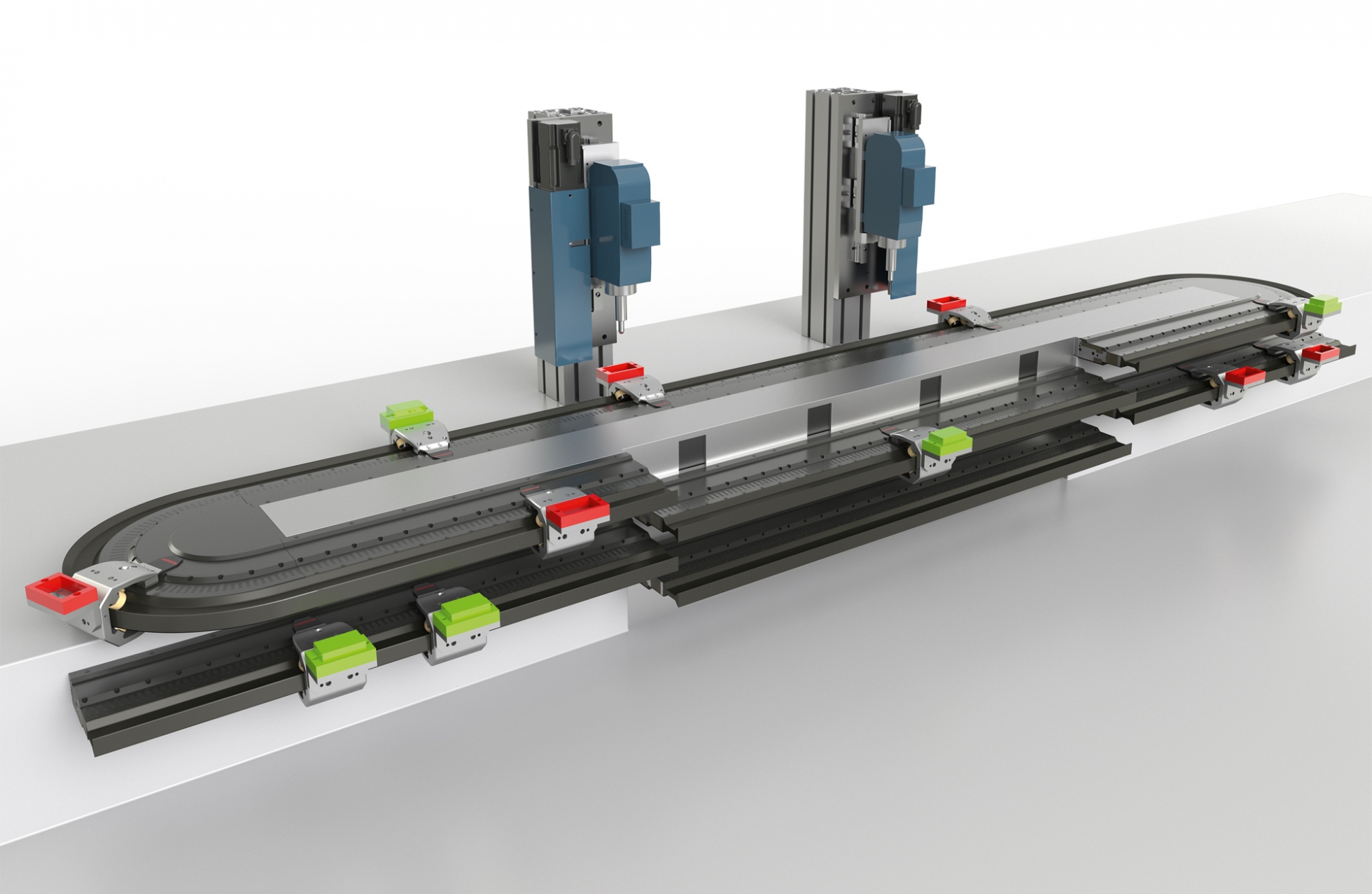

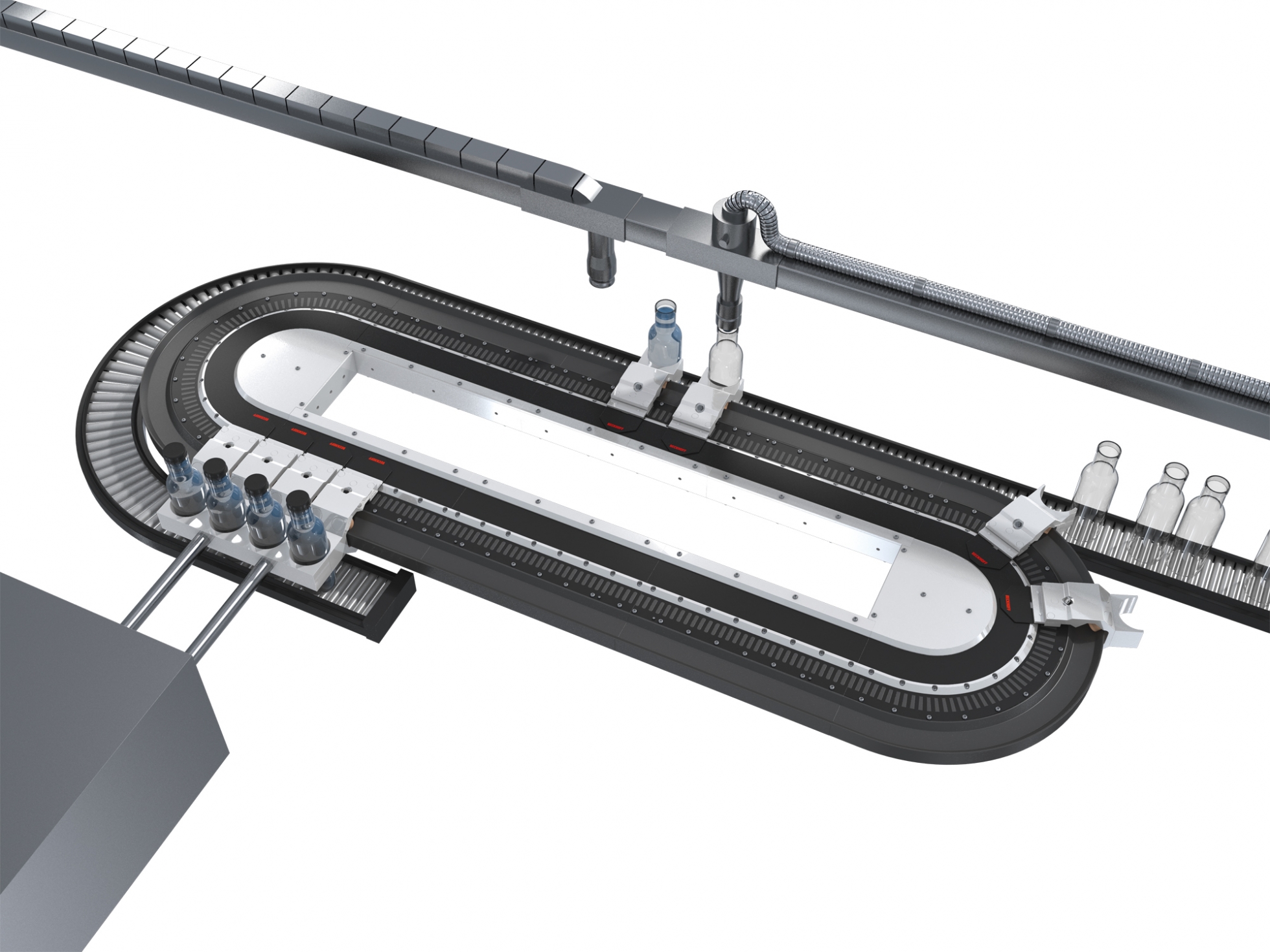

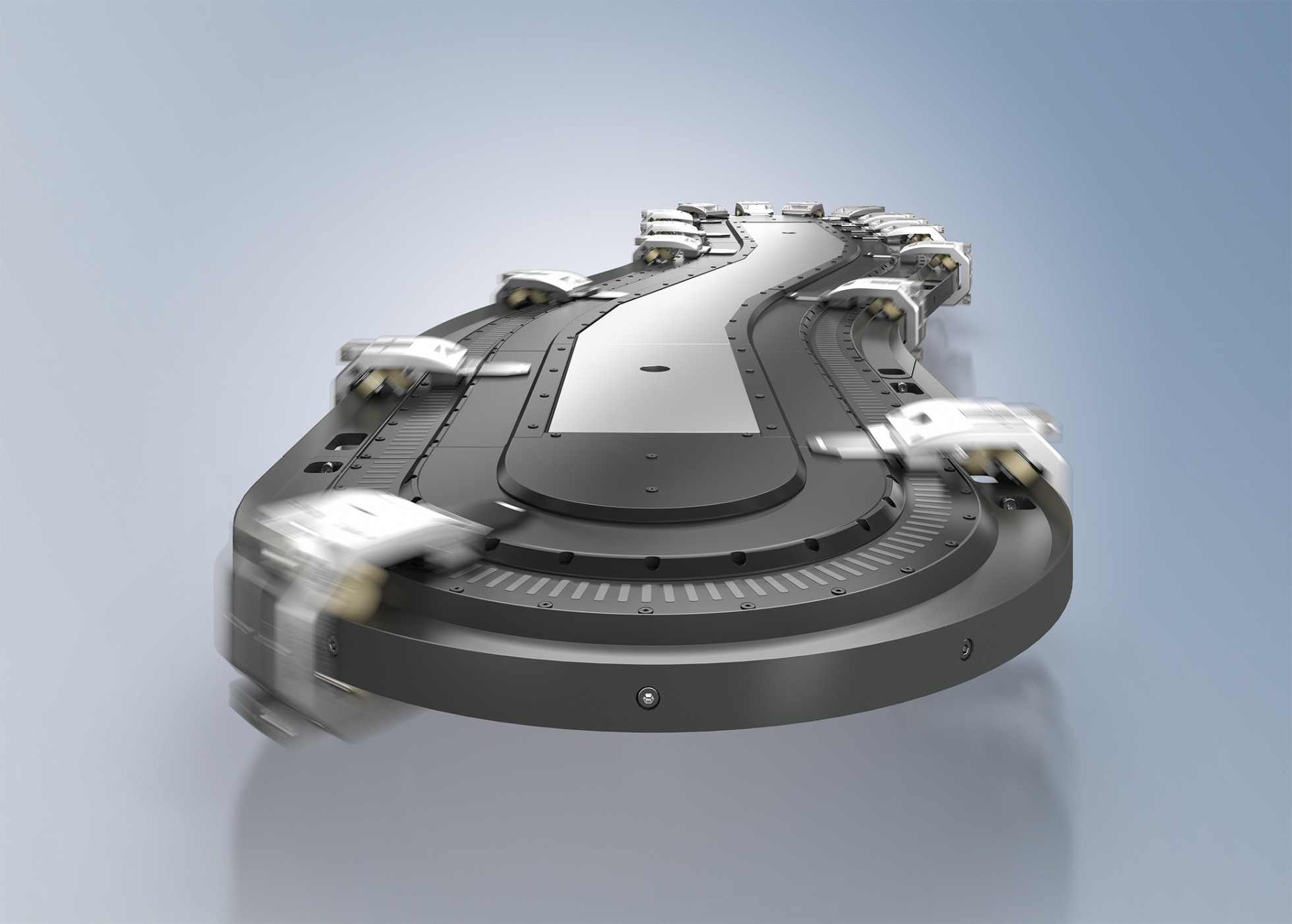

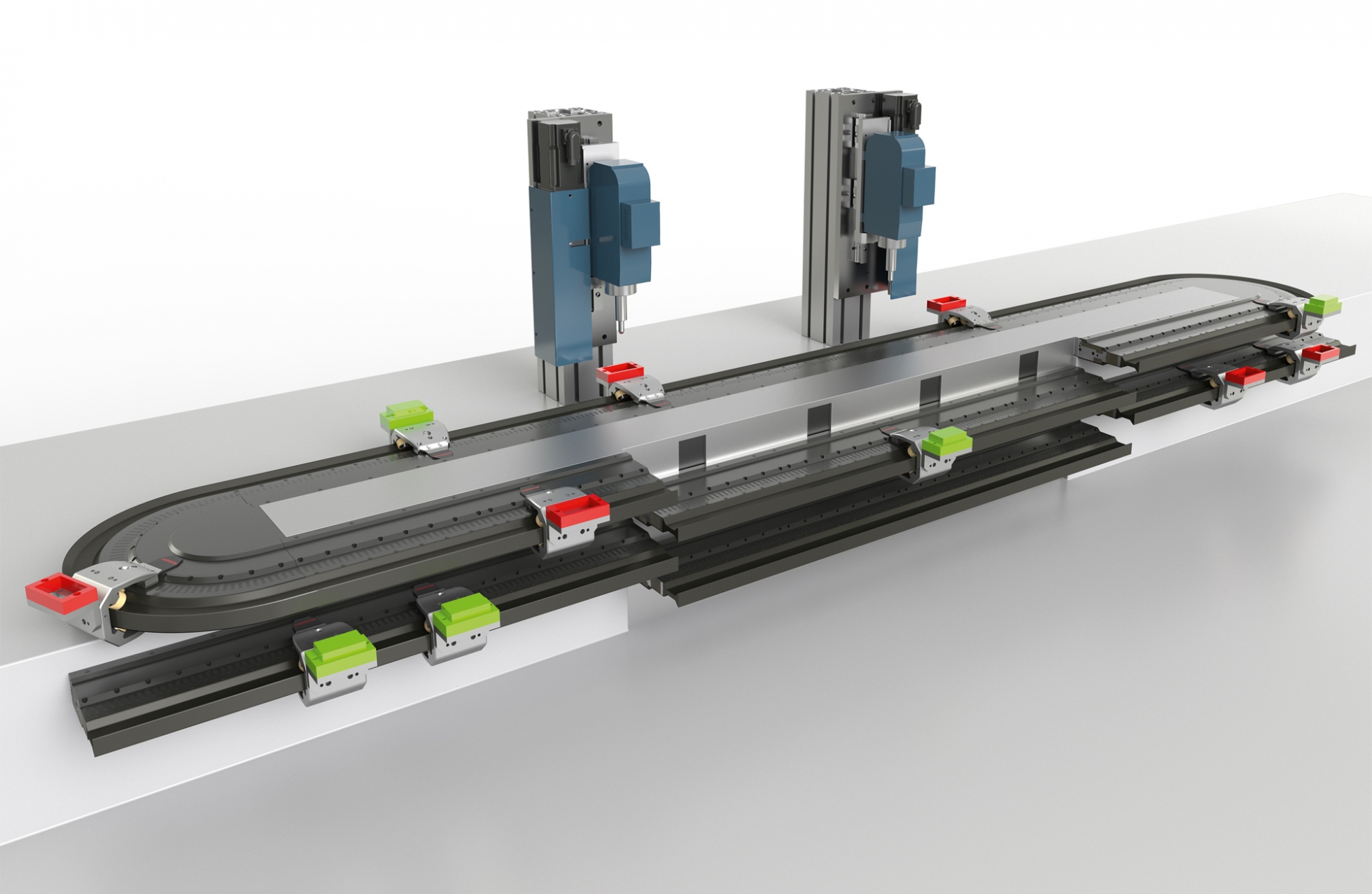

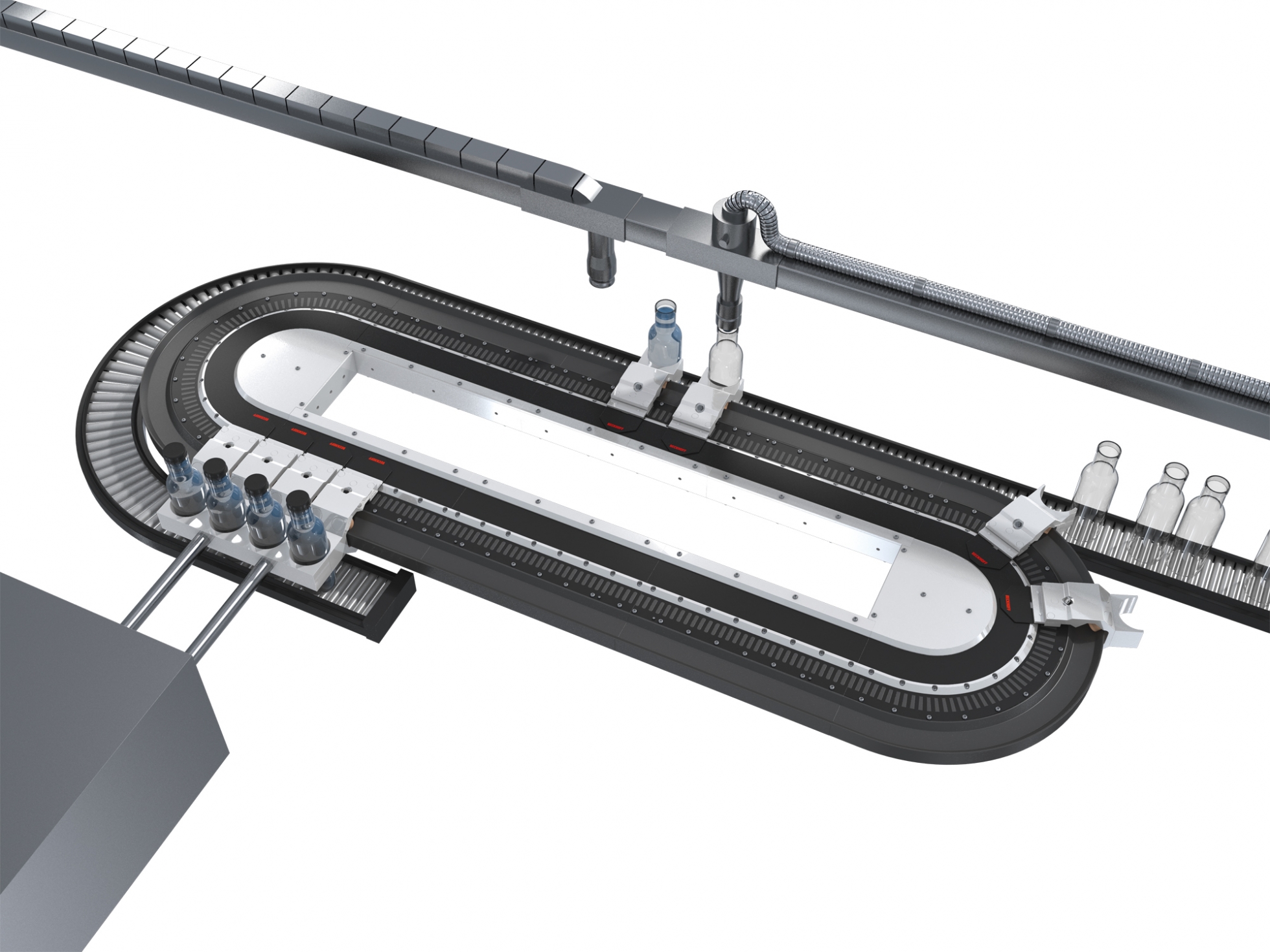

With the XTS linear transport system, Beckhoff offers a proven drive solution in which magnetically driven movers move along a travel path of fully integrated motor modules. An Industrial PC with the TwinCAT automation software enables the independent control of the movers with individual motion profiles. This results in many system-related benefits: The transport system is ready for operation immediately after assembly, as power electronics and displacement measurement are included in the XTS motor modules and the movers are completely passive. Due to different geometries of the motor modules, both an open and a closed travel path can be created and the machine footprint can be reduced by individual track layouts. The XTS not only replaces conventional conveyor belts, but also enables an innovative design of the entire machine. With the flexible motion profiles, simple to highly complex processes can be realized and the entire manufacturing process can thus be optimized.

Features / strengths

– Multi-directional transmission combining linear motors and rotary motors

– High flexibility: customized movement path, free placement and assembly of tracks

– The movers operate independently, and the number can be flexibly increased or decreased

– High-precision positioning, greatly improving productivity

– Able to convert products and formats on the fly to meet zero downtime

–The production batch size can be adjusted through the software

–Straight-line and curved structures successfully reduce floor space

–Can convert vertical process into horizontal process

– Standardization of mechanical components to shorten time to market

Specification in detail

maximum acceleration

100 m/s²

payload

20 kg �(even more in coupled operation)

repeat accuracy

(±) 10 µm